No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941898659

Semiconductor overhead monorail system wheels feature high speed, non-marking performance, cleanliness, positioning accuracy down to 0.1 mm, and smooth operation.

In semiconductor production, overhead monorail systems are responsible for transporting delicate materials. Any slight vibration, dust, or static electricity can impact production efficiency and product yield. Therefore, the wheels for high-speed, precision monorail systems are a core component for system operation, and their performance directly determines the smoothness, safety, and cleanliness of transportation.

Anti-static properties

The semiconductor production environment is extremely sensitive to static electricity, and static buildup can damage wafers or cause electronic component failure. Therefore, monorail system wheels are typically constructed with anti-static materials or have conductive fillers added to their polyurethane tires. This allows the wheels to effectively dissipate static electricity during high-speed rolling, ensuring material and equipment safety.

Clean and dust-free

To prevent contamination in the semiconductor production environment, wheel materials must be clean and dust-free. Polyurethane or high-performance engineering plastics (PEK, nylon) are not only wear-resistant but also maintain surface integrity over long periods of use, eliminating particle and debris generation, ensuring cleanroom standards are met.

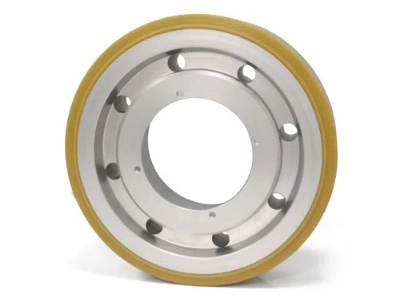

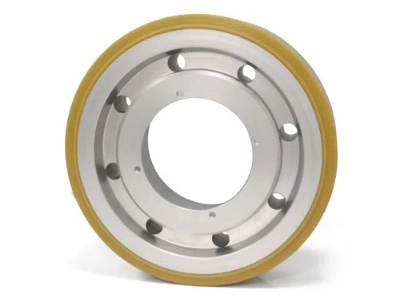

Non-marking design

Monorail systems often operate on sensitive, precision tracks, requiring wheels with non-marking rolling capabilities. High-precision polyurethane tires combined with stainless steel or aluminum wheel cores ensure that the wheels leave no marks on the track or bearing surface during high-speed operation or turning, maintaining a clean environment.

High speed and low friction

Semiconductor production lines often require high-speed material handling to improve production efficiency. Monorail wheels utilize low-friction materials and precision bearings to reduce rolling resistance, enabling the vehicle to maintain stability even at high speeds, accelerating production.

Low vibration and smooth rolling

To protect precision equipment and sensitive materials, wheels must exhibit low vibration and smooth rolling. Optimizing the tire hardness, wheel diameter, and wheel core design effectively absorbs minor vibrations, ensuring smooth operation of the monorail system and minimizing impact on materials such as wafers and semiconductor chips.

Precise positioning

Semiconductor elevated monorail systems are often used for automated handling and precision assembly, requiring extremely high positioning accuracy. The wheels must maintain precise operation to ensure a stable transport trajectory and minimize parallel error. Combined with the guide system, they achieve high-precision alignment, providing reliable support for automated handling.

Precision material handling equipment wheels

High-speed, precision semiconductor elevated monorail system wheels are not only load-carrying and transport tools but also key components for ensuring clean, stable, and efficient production. These wheels offer anti-static, chip-free, non-marking, high-speed, low-friction, low-vibration, smooth rolling, and precise positioning properties. They meet the stringent safety, cleanliness, and efficiency requirements of semiconductor production lines and are an indispensable core component of modern semiconductor automated logistics systems.

High-performance EMS wheels engineered for maximum durability, smooth operation, and minimal downtime in automated monorail systems.

Ensure your EMS reliability with our critical load-bearing wheels, designed for ton-level dynamic loads and non-stop operation in smart factories.

Discover how intelligent EMS wheels power overhead material handling systems, maximizing space and efficiency for smart factories.

Discover EMS wheels - the core driving force behind smart logistics systems. These precision engineered wheels enable high-precision, intelligent, and efficient material handling for modern smart factories.