No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

High-capacity, floor-protecting polyurethane coated wheels for medical/lab equipment offer quiet, hygienic, vibration-dampened mobility compliant with strict industry standards.

In the medical and laboratory industries, precision, cleanliness, and reliability are non-negotiable requirements for equipment mobility. Polyurethane coated wheels for medical equipment are engineered to address these critical demands, delivering smooth, quiet, and contamination-free performance that safeguards sensitive instruments and supports strict hygiene protocols.

What Are High Capacity and Floor Protection Polyurethane Coated Wheels For Medical And Laboratory Equipment?

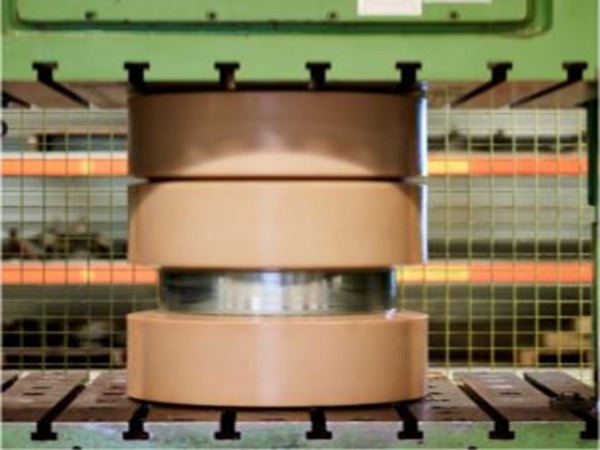

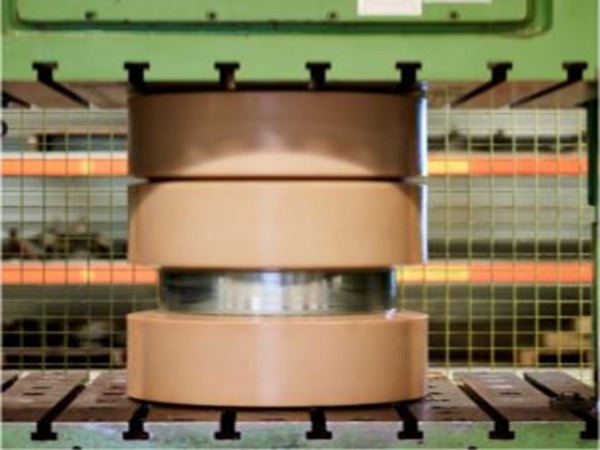

Polyurethane (PU) coated wheels are specialized mobility components featuring a durable polyurethane layer bonded to a core (typically metal or plastic). Designed explicitly for medical and laboratory settings, these wheels combine the strength of the core with the elasticity and hygiene properties of polyurethane, making them ideal for environments where vibration control, sterility, and longevity are paramount.

Key Applications Of Polyurethane Coated Wheels In Medical & Laboratory Fields

Polyurethane coated wheels for laboratory equipment and medical devices are widely adopted across critical scenarios, including:

Medical Carts & Hospital Trolleys: Ensure smooth, silent mobility in busy clinical environments, preventing noise disruption in patient areas and maintaining stable transport of supplies.

Laboratory Instruments: Essential for polyurethane coated wheels for laboratory centrifuges, analyzers, and testing machines, where precise movement and vibration dampening are critical to accurate test results.

Specialized Medical Devices: Support internal mechanisms of infusion pumps, automatic sampling machines, and surgical equipment, thanks to wear-resistant and stable performance.

Cleanroom Equipment: Perfect for sterile environments, due to non-shedding and easy-to-clean properties.

Why Choose Polyurethane Coated Wheels For Medical & Laboratory Use?

Medical-grade polyurethane coated wheels stand out from traditional rubber or plastic wheels with unique advantages tailored to industry needs:

Superior Elasticity & Vibration Control: Absorb shocks and reduce vibration, protecting delicate medical and laboratory instruments from damage and ensuring accurate readings—critical for centrifuges and analytical equipment.

Quiet & Non-Marking Design: Operate silently to maintain peaceful clinical environments, while the non-marking polyurethane layer prevents floor scratches in hospitals and labs.

Medical-Grade Hygiene Compliance: Manufactured with FDA-approved or USP Class VI compliant polyurethane, these wheels resist bacteria growth, are easy to disinfect, and meet strict medical hygiene standards.

Anti-Slip & Wear Resistance: Provide stable grip on smooth or sterile floors, reducing the risk of equipment tipping. The polyurethane coating offers excellent wear resistance, extending wheel lifespan even with frequent use.

Chemical Stability: Resist corrosion from common laboratory chemicals, disinfectants, and medical fluids, ideal for harsh cleaning routines in healthcare settings.

The Preferred Mobility Solution For Medical & Laboratory Industries

For manufacturers and operators of medical and laboratory equipment, polyurethane coated wheels deliver unmatched value by combining durability, hygiene, and precision. Whether for hospital trolleys, laboratory centrifuges, or cleanroom devices, these wheels meet the strictest industry standards and support reliable, long-term operation. Choose medical-grade polyurethane coated wheels to enhance equipment performance, protect sensitive instruments, and maintain compliance with healthcare and laboratory regulations.

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.