No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

Polyurethane traction wheels ensure clean, quiet, and precise motion for medical production lines, offering wear resistance, chemical durability, and reliable performance in sterile environments.

Polyurethane traction wheels ensure clean, quiet, and precise motion for medical production lines, offering wear resistance, chemical durability, and reliable performance in sterile environments.

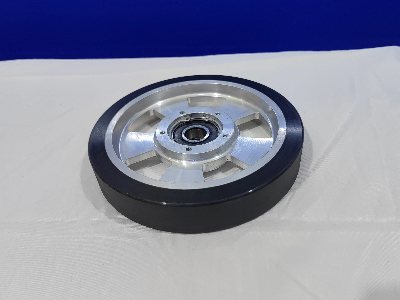

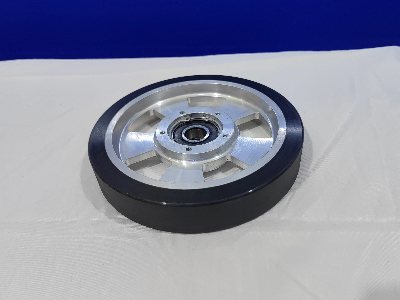

In modern medical production lines, precision, cleanliness, and reliability are critical factors that ensure the consistent quality of healthcare products. One essential component that plays a key role in this process is the polyurethane traction wheel.

Importance in medical manufacturing

Medical equipment and pharmaceutical production systems often involve automated conveyors, cleanroom transport platforms, and precision-guided vehicles (AGVs/RGVs). These systems require wheels that provide:

Smooth, stable motion to maintain accuracy in production.

Non-marking and clean operation to prevent contamination.

Durable traction for reliable performance in continuous operation.

Polyurethane traction wheels meet these demands, making them an indispensable part of the medical production environment.

Key features of polyurethane traction wheels

High wear resistance – polyurethane offers excellent abrasion resistance, ensuring long service life even under high-frequency operation.

Cleanroom compatibility – non-marking and low particle emission properties make them suitable for sterile environments.

Low noise & vibration – smooth rolling reduces operational noise, enhancing comfort and stability in sensitive medical facilities.

High load capacity – capable of supporting heavy equipment and maintaining precision movement.

Chemical resistance – resistant to cleaning agents and disinfectants commonly used in medical production environments.

Polyurethane traction wheels are widely used in

Pharmaceutical packaging conveyors

Medical device assembly lines

Automated cleanroom transfer systems

Guided transport vehicles (AGVs/RGVs)

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.