No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

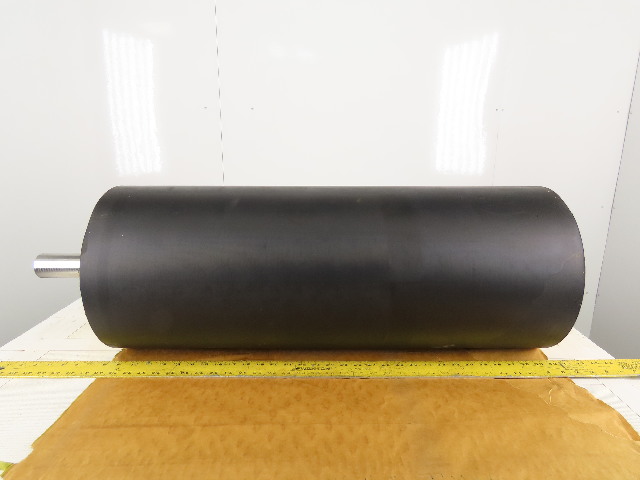

Polyurethane rollers for large printing presses are cylindrical, key components consisting of a metal core coated with an elastic material (primarily polyurethane). They are widely used in various large-scale printing equipment and related machinery.

Polyurethane rollers for large printing presses are cylindrical, key components consisting of a metal core coated with an elastic material (primarily polyurethane). They are widely used in various large-scale printing equipment and related machinery. They achieve core functions such as ink transfer, paper lamination, and image transfer through surface elastic contact. They serve as a bridge between the printing press's power system and the print media, directly impacting the clarity, color uniformity, and operational stability of printed products.

Why is polyurethane the preferred material for polyurethane rollers?

When it comes to polyurethane rollers for large-scale printing presses, polyurethane has become an industry benchmark due to its unique properties:

• Compatibility with the printing environment: The printing process frequently comes into contact with UV inks, solvents, and other chemicals. Polyurethane offers excellent corrosion resistance, resisting the acid and alkali content of inks, thus avoiding the cracking and hardening problems associated with traditional rubber materials due to chemical reactions.

• Balanced hardness and elasticity: Printing requires stringent hardness for polyurethane rollers. Polyurethane's shore hardness can be precisely controlled (e.G., a standard value of 85a). This ensures stable pressure on the paper while also compensating for variations in paper thickness through subtle elasticity, improving printing accuracy.

• Wear and fatigue resistance: When operating at high speeds (some equipment exceeds 300 meters per hour), polyurethane exhibits 3-5 times the wear resistance of ordinary rubber. It resists wear and deformation during long-term, high-frequency operation, significantly extending its service life.

Key features of polyurethane rollers for large printing presses

• Anti-falling coating: A high-temperature vulcanization process creates a tight bond between the polyurethane layer and the metal roller core, preventing coating peeling and blistering caused by alternating hot and cold temperatures and pressure shock, reducing downtime and maintenance.

• UV ink resistance: The specialized formula withstands the high temperatures (80-120°c) and ultraviolet radiation of the UV curing process, preventing aging and yellowing of the polyurethane layer and ensuring long-term printing consistency.

• Anti-piling design: A special textured surface treatment reduces ink accumulation, making it particularly suitable for high-speed printing and minimizing image defects.

• Customizable hardness: Customizable shore hardness ranges from 60a to 95a, allowing for flexible adjustments based on printing materials (paper, plastic film, etc.) and process requirements to meet diverse production requirements.

Applications of polyurethane rollers for large printing presses

• High-speed rotary presses: Suitable for high-volume printing of newspapers and periodicals, their high wear resistance and stability ensure uniform ink transfer during continuous production, meeting the needs of efficient printing.

• Gravure/flexographic printing equipment: Suitable for fine-detail printing on plastic packaging and labels. Its solvent resistance and surface smoothness ensure precise ink transfer and enhance image edge definition.

• UV specialty printing machinery: In UV printing applications such as gift boxes and cigarette packs, its UV radiation resistance ensures stable operation, preventing aging of the polyurethane layer and affecting print quality.

• Inkjet printer rollers: As an accessory for associated equipment, they elastically cushion paper tension to prevent tearing, while also reducing static electricity and preventing ink from attracting impurities.

Mailun's customization capabilities: Full-service guarantee from request to finished product

Mailun has specialized expertise in customizing polyurethane rollers for large-scale printing presses, offering customers highly flexible and precise direct supply services:

• Technical extensiveness: With over 10 years of experience in polyurethane formulation research and development, we can customize solutions based on customer equipment models, printing materials, and process parameters, precisely matching 85a and other hardness requirements.

• Production guarantee: Equipped with an automated polyurethane casting line and utilizing an integrated high-temperature vulcanization process, we ensure uniform coating thickness (≤0.1mm tolerance) and 100% compliance with anti-chipping and anti-blistering standards.

• Strict quality control: Each roller undergoes 12 verification criteria, including hardness testing, wear resistance testing, and dynamic balancing testing, to ensure compatibility with the high-intensity operations of high-speed rotary printing presses.

• Service system: We provide a comprehensive service process from request communication, sample production, to mass delivery. We support expedited orders and respond to technical inquiries within 36 hours to ensure continuous production.

Mailun's polyurethane wheels for large-scale printing presses, made from polyurethane and featuring customized services, provide the printing industry with key components that are highly elastic, wear-resistant, and adaptable, helping companies improve production efficiency and print quality. Filson also offers related polyurethane rollers for heavy-duty material transport, AGVs, and RGVs.

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.