No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

Precision wafer transport cart wheels are cleanroom-compliant polyurethane wheels that ensure contamination-free, smooth movement, low particulate emissions, and chemical resistance during the transportation of sensitive semiconductors.

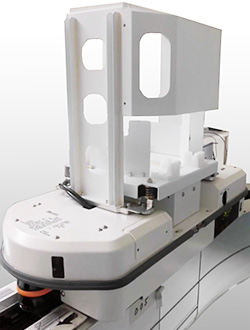

Cleanroom OHS (Over Head Shuttle) Wheels are polyurethane (PU) wheels engineered specifically for ISO Class 1-5 high-cleanliness environments. They are core-compatible with semiconductor Overhead Shuttles (OHS), wafer transport carts, Automated Guided Vehicles (AGVs), and cleanroom material handling equipment. Their core value lies in delivering contamination-free, smooth, and shock-absorbing transportation for sensitive loads such as wafer cassettes and FOUPs through ultra-low particle emission, non-shedding and non-marking design, and excellent chemical resistance—perfectly meeting the stringent cleanliness and precision requirements of semiconductor manufacturing.

The Wheels Feature Three Core Advantages:

Ultimate Cleanliness Protection: Crafted from certified medical-grade polyurethane, they achieve ultra-low particle emission standards for cleanrooms. The non-shedding and non-marking design prevents floor damage and environmental contamination, ensuring the integrity of clean environments like wafer fabrication areas.

All-Scenario Durability: Resistant to common cleaning agents and solvents, these wheels are paired with precision-machined aluminum or stainless steel cores. Each wheel supports a maximum load of 150 kg, combining high load capacity with superior shock absorption to effectively reduce vibration during transportation and protect fragile wafer components.

Flexible Adaptability: Custom sizes are available, with options for individual wheels or complete casters (swivel and rigid models). Hub materials include stainless steel or aluminum, making them suitable for OHS, wafer transport carts, AGVs, and various cleanroom material handling equipment.

Key Technical Specifications:

Material: High-purity medical-grade and instrument-grade polyurethane (PU)

Core Material: Precision-machined aluminum or stainless steel

Standard Diameters: 3", 4", 5", 6" (custom sizes available)

Load Capacity: Up to 150 kg per wheel (customizable for higher loads)

Applications: Ideal for ISO Class 1-5 cleanrooms, including Overhead Shuttles (OHS), wafer transport carts, AGVs, cleanroom transport carts, and material handling equipment.

Mailun wheels undergo precision manufacturing, cleaning, and packaging in a controlled environment to ensure they are ready for integration into your most sensitive operations. They are the trusted choice for reliable, contamination-free mobility in the world’s most advanced semiconductor facilities. To find a tailored solution for your specific cleanroom cart, browse our catalog or contact our engineering team for personalized support.

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.