No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

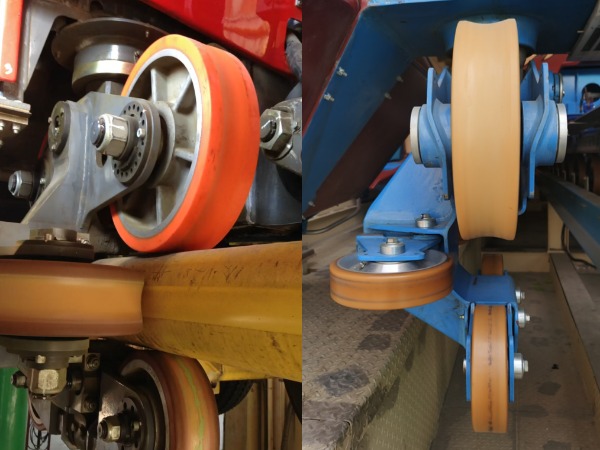

Skid conveyor wheels are used in automotive welding, painting, and assembly applications. They utilize high-hardness polyurethane (90-98A) overmolding technology, offer a single wheel load capacity of 1-5 tons, are impact-resistant, wear-resistant, and quiet.

Professional polyurethane guide wheels for automotive production lines are specifically developed for skid conveyor systems. They utilize high-hardness polyurethane (90-98A) overmolding technology, offer a single wheel load capacity of 1-5 tons, and are temperature-resistant from -30°c to 100°c. Optimized wheel diameters (32-120mm) and widths address the challenges of vehicle body conveying deviation, noise, and chemical corrosion, and are compatible with the entire welding, painting, and final assembly process. Custom sizes (150-600mm) are available, with 72-hour proofing and a 30% increase in production line efficiency.

In the automotive intelligent manufacturing system, skid conveyors are the "blood vessels" of the three core processes of welding, painting, and final assembly, while guide wheels are the "joints" that ensure conveying accuracy and stability. Polyurethane-coated guide wheels, with their impact resistance, wear resistance, and low noise levels, are becoming a revolutionary component replacing traditional metal wheels. This article will provide an in-depth analysis of their technical characteristics, application suitability, and application cases in the automotive industry.

Why is upgrading polyurethane guide wheels essential for automotive production lines?

1. Addressing the pain points of the traditional metal wheel industry

Noise and vibration reduction: Polyurethane elastomer absorbs shock from equipment operation, reducing noise by over 40% and protecting precision body parts (especially sensors on welding lines).

Anti-slip and anti-drift: A high coefficient of friction (μ≥0.8) ensures smooth vehicle body movement during high-speed conveying, eliminating assembly errors.

Clean and pollution-free: No oil volatilization, meeting the class 100,000 cleanliness requirements of paint shops and preventing paint contamination.

2. Breakthrough performance in extreme operating conditions

Wide temperature resistance: Stable from -30°c to +120°c (e.G., 80°c in paint drying lines and -20°c in cold chain warehouses).

Chemical resistance: Resistant to common chemicals used in automotive production lines, such as electrophoretic fluids and degreasers.

Lifetime lubrication-free: Polyurethane's self-lubricating properties reduce maintenance frequency and downtime costs.

Key parameter customization guide (adjusted to automotive production line-specific scenario)

Wheel diameter: 32-50mm for low-speed idlers; 55-80mm for high-speed logistics channels; 120mm for high-precision inspection stations.

Wheel width: Allow 8mm for installation. Baffle height ≥ 0.8 times the rubber layer thickness (to prevent derailment).

Hardness: 90A-98A for welding lines (impact resistance); 70A-85A for final assembly lines (prioritized for noise reduction).

Applications

Skid conveyor lines in automotive final assembly workshops

Skid guide systems for paint production lines

Heavy-duty logistics conveyor lines and custom automated conveying equipment

Manufacturer strength

As a professional polyurethane-coated wheel manufacturer, Mailun utilizes advanced casting, molding, and processing equipment to ensure the dimensional accuracy and bond strength of its guide wheels. All products undergo wear and load testing to ensure long-term stable operation in high-stress environments such as automotive conveyor lines.

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.