No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

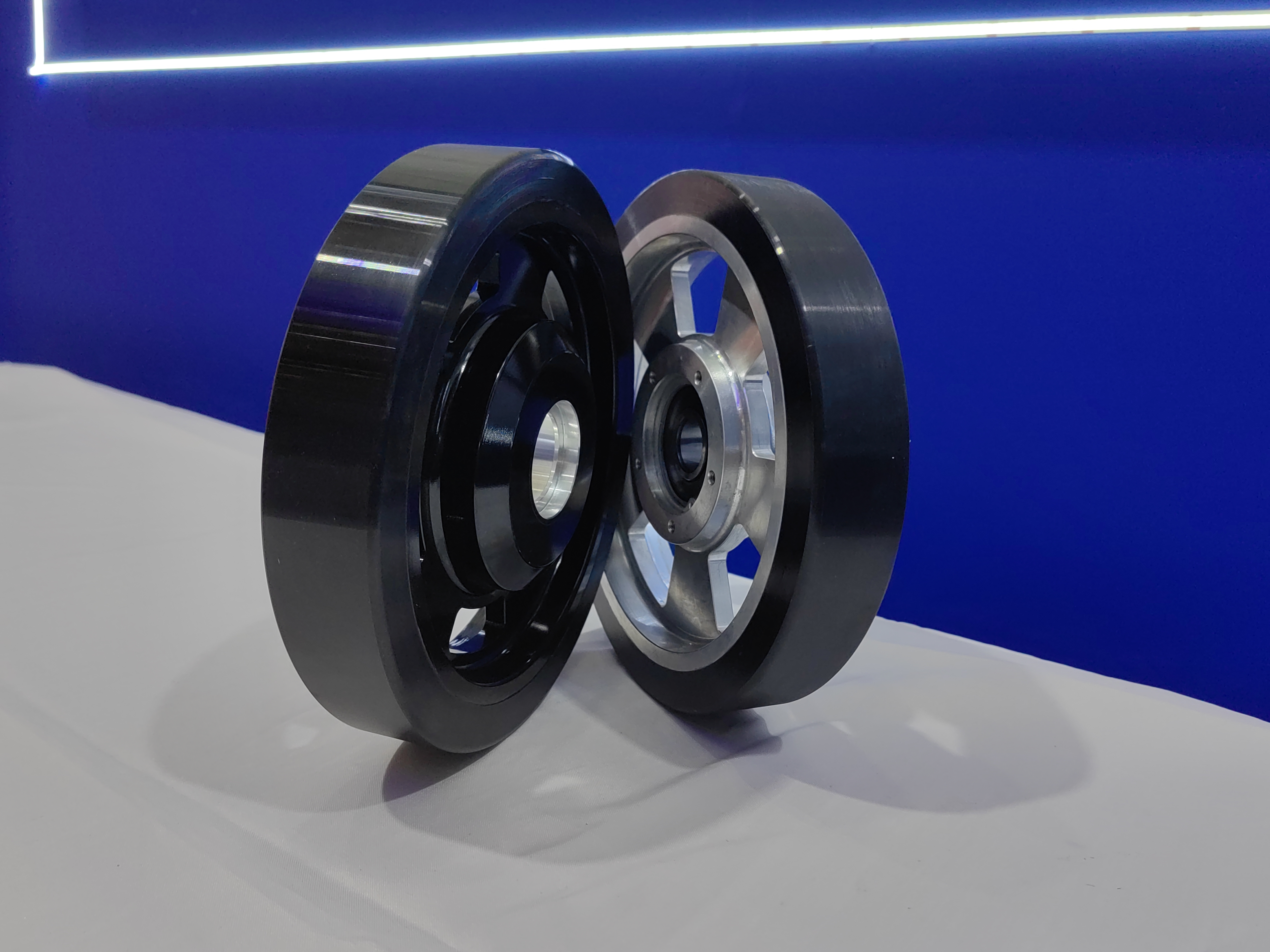

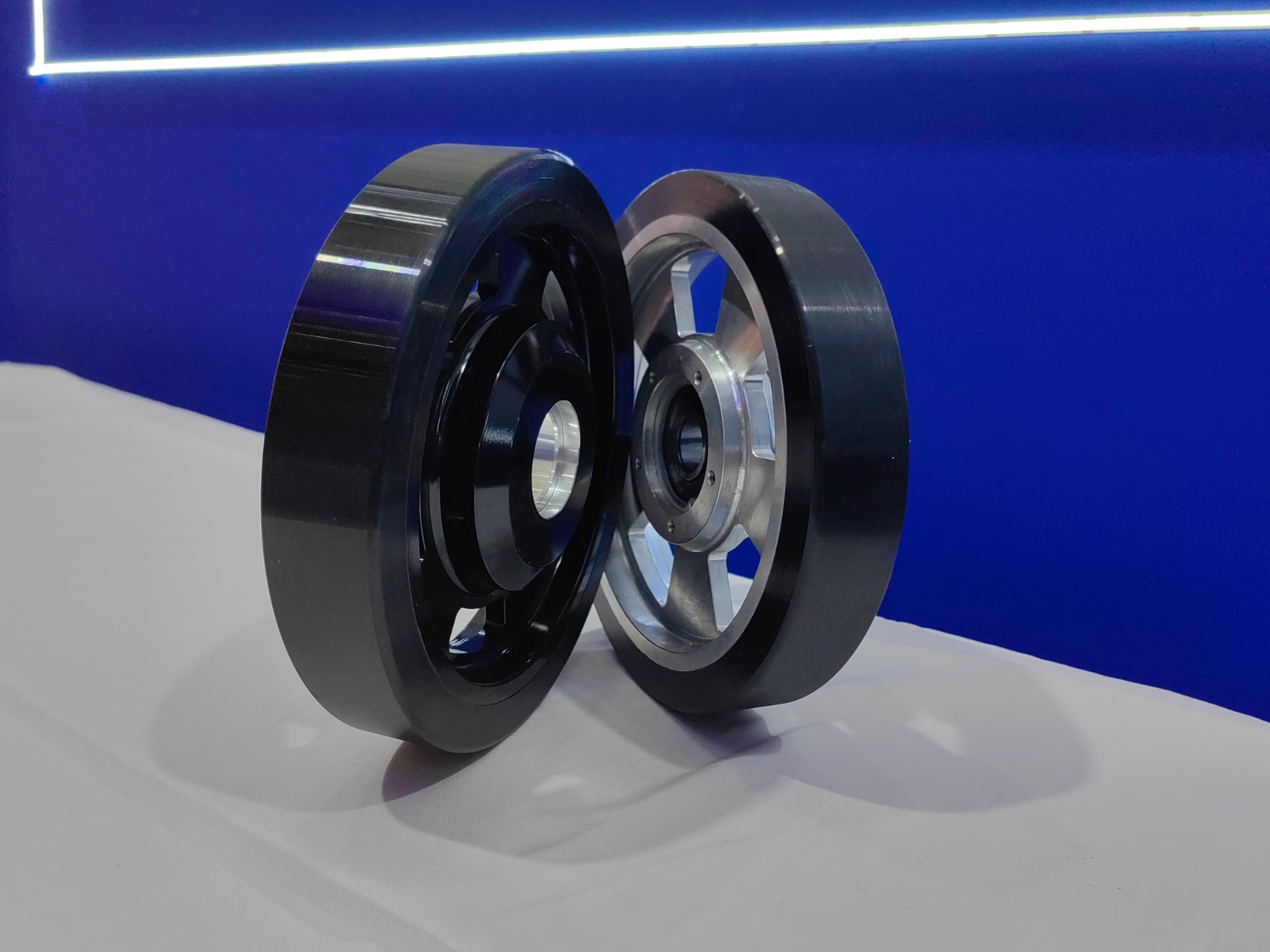

Electric monorail system wheels consist of a stainless steel core with a polyurethane coating and are used in meat hanging lines, dairy filling tracks, and smart food delivery monorail systems.

Electric monorail system wheels consist of a stainless steel core with a polyurethane coating and are used in meat hanging lines, dairy filling tracks, and smart food delivery monorail systems.

Core requirements for conveyor systems in the food industry

• In food processing, central kitchens, and packaging lines, electric monorail wheels must meet three stringent standards:

• Food safety certification: FDA and EU 10/2011 certifications ensure zero risk of contamination migration;

• Extreme environment resistance: Resistant to high-temperature steam cleaning (100°c+), corrosion from acid and alkali cleaning agents, and suitable for cold chain environments down to -30°c;

• Quiet and anti-slip: Friction coefficient ≥ 0.6 on wet surfaces, noise ≤ 65db, avoiding production disruptions.

• Traditional pain points: Ordinary metal wheels are prone to rust and bacterial growth, rubber wheels are prone to aging and peeling, and nylon wheels are brittle and crack at low temperatures, all of which fail to meet food-grade hygiene requirements.

Advantages of food-grade polyurethane wheels

• Precision manufacturing, stable operation

Each wheel undergoes CNC precision machining and dynamic balancing to ensure zero deflection and vibration even at high speeds (≤15 m/s), ensuring smooth transport on the monorail system.

• All-stainless steel construction

The wheel core and shaft assembly is constructed of SUS304 or SUS316 stainless steel, offering excellent corrosion resistance and withstanding high humidity, salt spray, acid and alkaline cleaning agents, and high-temperature steam sterilization, making them suitable for CIP/SIP cleaning processes.

• High load capacity

Polyurethane exhibits a certain degree of hardness and resilience, enabling the transport of heavy foods such as beverages, meat, and seafood.

Typical applications

• Meat processing suspension lines

Antibacterial silver ion coating on the wheel inhibits E. coli growth and is HACCP certified.

Low-temperature brittleness formula (-30°c) ensures stable operation in cold storage environments.

• Dairy filling track

White, pollution-free polyurethane material prevents pigment migration and complies with GMP workshop standards.

Precise positioning (±2mm) ensures millimeter-level alignment between the filling valve and the bottle neck.

• Intelligent food delivery monorail system

Low-noise design (≤60db), suitable for restaurant conveyors and AGVs.

Anti-slip ribs and conductive formula eliminate the risk of static dust absorption.

Reference: After adopting this solution, an international fast food chain's central kitchen reduced equipment cleaning time by 40% and annual maintenance costs by 280,000 yuan.

Customized service and warranty

Modular design: Supports quick adaptation to wheel diameters from 100 to 250mm, providing load-hardness matching solutions.

Verification system: Passes 72-hour full-load fatigue testing (ISO 22877) and SGS material safety testing.

Intelligent operation and maintenance: Optional RFID chip provides real-time monitoring of wheel wear and lifespan warnings.

Mailun maintains quality while offering cost-effective pricing. Custom wheels of varying sizes, hardnesses, colors, and even new wheels are available. Welcome to contact us by email.

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.