No.19 Electronic Information Industry Park, Anfeng Town, Dongtai City, Jiangsu,China WhatsApp: +86 19941574218

Discover the best FDA hygiene wheels for food processing. Our non-marking, silent, and corrosion-resistant casters help protect your floor.

In the strictly regulated food and beverage industry, every component is critical. As the intersection of safety, efficiency, and operational costs, caster performance directly impacts core business operations. We have built a professional, customized caster solution around three core pillars to fully meet the rigorous demands of the global food industry.

Four Key Requirements for Food Industry Caster Selection:

Rigid Hygiene & Safety Standards: Casters must feature anti-rust, anti-shedding, and anti-particle contamination properties to avoid product recall risks and protect brand reputation.

Complex Environment Adaptability: Whether in deep-freeze environments or high-temperature baking lines, casters must withstand high-frequency, high-pressure chemical washdowns.

Strict Compliance Certification: They must comply with international standards and provide traceable certification documents to ensure smooth audits and global market access.

Classification by Core Material

Polyurethane (PU) Food-Grade Casters (Recommended)

Features: Non-marking, silent, and wear-resistant. Resistant to fats, oils, mild chemical cleaners and non-slip. Smooth surface for easy cleaning. Compliant with FDA and EU 10/2011 food standards.

Applications: Food processing lines, catering kitchens, baking workshops, and supermarket shelving. The most versatile type in the industry.

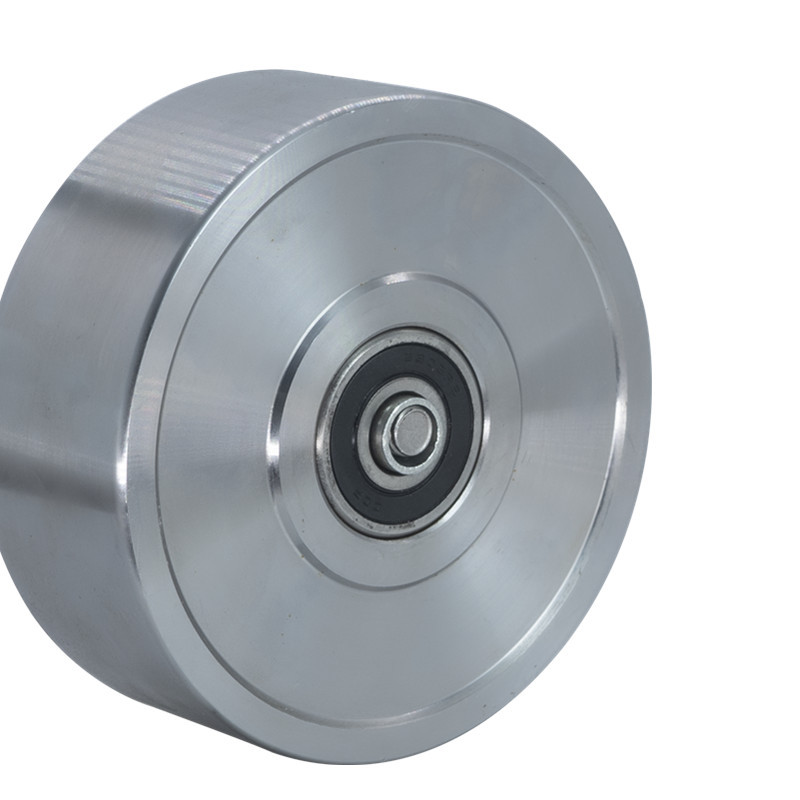

Stainless Steel Food-Grade Casters

Features: Brackets and wheel cores are made of 304/316 stainless steel. Treads can be PU, nylon, or solid stainless steel. Superior corrosion resistance; withstands frequent high-pressure chemical cleaning (acid/alkali) without risk of rust.

Applications: Meat processing, seafood processing, and dairy production lines requiring extreme hygiene, especially in humid or saline environments.

Nylon (PA) Food-Grade Casters

Features: Lightweight, low-temperature resistant (down to -40°C), low water absorption, and high load capacity.

Applications: Cold chain logistics and flash freezers (below -20°C). Prevents the low-temperature embrittlement common in standard casters.

Classification by Structure and Function

Swivel Casters

Features: 360° rotation for maximum maneuverability. Can be equipped with braking devices (toe brakes, side brakes).

Specialized Food Design: Sealed bearings and full side guards to prevent flour, sugar, and moisture ingress.

Applications: Equipment requiring frequent turning, such as food carts, prep tables, and AGVs.

Rigid (Fixed) Casters

Features: Moves in a straight line only. Offers higher stability and load capacity than swivel casters of the same size.

Applications: Heavy equipment (large refrigerated cabinets, conveyor lines). Usually paired with swivel casters (e.g., 2 rigid wheels in front + 2 swivel wheels in back).

Conclusion

In the food industry, where safety and efficiency are paramount, high-quality casters are a strategic investment. They act as both the guardians of compliant operations and the enablers of production efficiency. We invite you to partner with us. Leveraging our professionally customized food-grade caster solutions, we can protect your product safety, empower your workforce, and help your business move steadily forward in the global market. Contact us !

Compare Polyurethane, Nylon, and TPR based on particulate shedding, chemical resistance, and ESD properties. Learn how choosing the right wheel can improve product yield in semiconductor, pharmaceutical, and biotech environments.

Direct‑fit polyurethane wheels for pallet jacks: 1–3 t load range, superior tear & aging resistance, quieter operation and reduced maintenance.

Polyurethane-coated wheels are the core component for AMR (Autonomous Mobile Robot) stability—offering high load capacity, 3-5x wear resistance vs rubber, wide temp adaptability, and low noise.

Specialized industrial wheels and casters for semiconductor manufacturing: ensuring cleanroom purity, vibration-free stability, and heavy-load efficiency for maximum chip yield.